Generation P2.e

is a coaxial planetary gear unit in a 2- and 3-stage design.

+

Fast turnaround, direct from our Drive Technology Centre in Montreal, Canada.

Built and Shipped in as little as

From Canada!

P2.e Overview

Wide gear ratio range

The large gear ratio range of i= 15.2 to 332 enables all kinds of possible applications.

Direct bearing arrangement

With a direct bearing arrangement and no outer ring, the new full complement cylindrical roller bearing offers the optimum combinationof bearing service life and compactness.

Variable motor interfaces

A variety of options - such as direct mounting of SEW-EURODRIVE motors, input shaft assemblies, or IEC motor adapters - ensures excellent flexibility.

Direct motor mounting with integrated fan

The new fan concept gives generation P2.e a “best-in-class” thermal rating.

Gear unit design

Stages

Gear ratio i

Norminal torque MN2 kNm

P2P.002e – 052e

P3P.002e – 052e

Advantages of the P2.e coaxial planetary gear unit.

Maximum Efficiency

Generation P2.e has a very high thermal rating and therefore requires no additional external cooling usually.

Compact Design

P2.e makes the most of tight installation spaces in machines and systems.

Flexible

A wide rage of options on the input and output side and the combination with our modular motor system create a large degree of freedom in machine design.

Simple

Different mounting types and output shafts enable quick and easy simple machine connection.

Fast & Local

Configured and assembled right here in Canada! There's no need to worry about long wait times, or getting support .

Industrial Crushers

From mining to material recycling, SEW-EURODRIVE Coaxial Planetary Gear Units deliver the efficiency, reliability, and raw power your operation demands. When uptime and performance matter most, trust SEW-EURODRIVE—engineered and supported locally for Canada’s toughest industries.

Premium Support and Local Assembly arcross Canada

Local Assembly, Service & Support Across Canada With Three Service hubs spanning across Canada, SEW-EURODRIVE offers local engineering, service, and assembly in Canada. Gear units are built, serviced, and supported directly by SEW-EURODRIVE experts—ensuring faster lead times, reliable parts availability, and responsive technical support anywhere in the country.

Smarter Operation with Drive Automation

Pair your gear unit with SEW-EURODRIVE frequency inverters for total control—monitor torque, optimize speed, and boost uptime through predictive maintenance.

Built Tough for Harsh Environments

Engineered with robust housings, hardened gears, and advanced sealing systems, these gear units thrive in demanding crusher environments—from dust and debris to constant vibration.

Make it your Drive. Custom is our standard.

Flexible and Modular Setup Adaptable mounting and configuration options allow easy integration into existing crusher systems, reducing installation time and cost.

Industries we serve.

Mining & Minerals Processing

Crushers are essential for breaking down ore, rock, and minerals. SEW-EURODRIVE planetary and industrial gear units are widely used in:

- Hard-rock mining

- Ore preparation plants

- Mineral extraction and beneficiation

Aggregates & Construction Materials

The crushed stone, sand, cement, and asphalt industries rely on crushers to produce consistent raw materials. SEW gear units power:

- Jaw crushers

- Cone crushers

- Impact crushers

Recycling & Waste Management

Crushers play a key role in reducing and processing recyclable materials. SEW gear units are commonly used in systems for: - Metal recycling - Concrete and asphalt recycling - Electronic waste shredding

Cement & Bulk Material Processing

The cement industry relies heavily on crushing and grinding equipment. SEW-EURODRIVE drives are used for:, Limestone crushing Clinker processing Pre-grinding systems

Industrial Mixers

When consistent mixing power meets precision engineering, SEW-EURODRIVE delivers. Our Coaxial Planetary Gear Units are designed to handle the most demanding industrial mixer applications—providing smooth, efficient, and reliable performance in every rotation.

Premium Support and Local Assembly arcross Canada

SEW-EURODRIVE provides local engineering, service, and assembly within Canada—a major advantage over imported systems. Each gear unit is built, serviced, and supported by Canadian experts, ensuring faster lead times and reliable technical assistance coast to coast.

Make it Your Drive. Custom is our standard.

Available in a range of mounting and configuration options, SEW-EURODRIVE gear units integrate easily into both new and existing mixer systems—simplifying installation and maintenance

Smarter Operation with Drive Automation

When paired with SEW-EURODRIVE’s variable frequency drives, operators gain precise control over mixing speed, torque, and direction—enabling optimized batch consistency and reduced wear.

Built Tough for Harsh Environments

Engineered with robust housings, hardened gears, and advanced sealing systems, these gear units thrive in demanding crusher environments—from dust and debris to constant vibration.

Industries we serve.

Food Processing

Mix with precision, consistency, and confidence. SEW-EURODRIVE gear motors deliver smooth, reliable performance that keeps your batching, blending, and emulsifying operations running flawlessly. Connect with our specialists to enhance your production line.

Pharmaceuticals

Engineered for accuracy in demanding environments. SEW-EURODRIVE drives provide controlled torque, precise speed regulation, and dependable operation for critical mixing applications. Speak with our experts to elevate process stability and safety

Waste Water Treament

Reliable performance for nonstop operations. SEW-EURODRIVE gear units deliver long-lasting, energy-efficient power for agitators and mixers used in aeration, digestion, and chemical dosing. Contact us to improve uptime and reduce maintenance headaches.

Chemical Manufacturing

Engineered for accuracy in demanding environments. SEW-EURODRIVE drives provide controlled torque, precise speed regulation, and dependable operation for critical mixing applications. Speak with our experts to elevate process stability and safety.

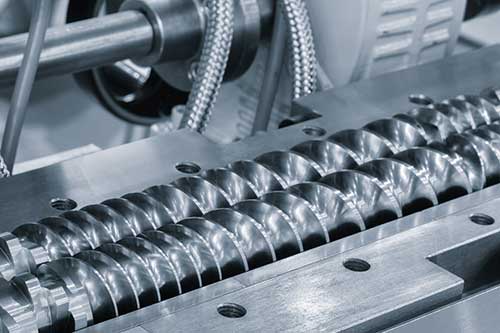

Industrial Screw Press

Industrial screw presses demand powerful, steady, and highly efficient drive systems. SEW-EURODRIVE’s Coaxial Planetary Gear Units deliver the torque, durability, and control required to keep screw presses running at peak performance—no matter the material or process.

Premium Support and Local Assembly arcross Canada

Local Assembly, Service & Support Across Canada With Three Service hubs spanning across Canada, SEW-EURODRIVE offers local engineering, service, and assembly in Canada. Gear units are built, serviced, and supported directly by SEW-EURODRIVE experts—ensuring faster lead times, reliable parts availability, and responsive technical support anywhere in the country.

Make it your Drive. Custom is our standard.

The modular design allows seamless integration with new or existing screw press systems. Multiple mounting configurations simplify installation and reduce downtime during commissioning or upgrades. Whether used for dewatering, compaction, extraction, or material separation, SEW-EURODRIVE Coaxial Planetary Gear Units deliver the torque, reliability, and efficiency your screw press needs. Engineered for continuous duty—and supported by Canadian experts—SEW keeps your operation moving.

Smarter Operation with Drive Automation

Pair your gear unit with SEW-EURODRIVE frequency inverters for total control—monitor torque, optimize speed, and boost uptime through predictive maintenance. In addition, pairing the gear unit with SEW-EURODRIVE variable frequency drives provides precise speed and torque control—critical for achieving optimal feed rate, pressing efficiency, and material output quality

Built Tough for Harsh Environments

Engineered with robust housings, hardened gears, and advanced sealing systems, these gear units thrive in demanding crusher environments—from dust and debris to constant vibration.

Industries we serve.

Pulp and paper

Engineered for abrasive, high-duty environments. SEW-EURODRIVE gear units are built to withstand the demanding conditions of fiber recovery, compaction, and industrial separation. Contact our specialists to increase system durability and operational uptime.

Food Production & Argicultural Processing

Consistent pressing power for clean, efficient production. SEW-EURODRIVE solutions deliver smooth, controlled performance ideal for juice extraction, oil pressing, and fiber separation. Reach out to discover how our drives can improve batch quality and yield.

Waste Water Treatment

Dependable torque for nonstop dewatering cycles. SEW-EURODRIVE drives provide reliable, energy-efficient power for sludge thickening and separation, even under fluctuating loads. Talk to our team to improve reliability across your treatment system.

Oil Extration

Reliable pressing power for maximum oil yield. SEW-EURODRIVE gear units deliver the high torque, steady speed, and long-duty performance essential for extracting oil from seeds, nuts, and biomass. Built for continuous operation and harsh conditions, our drives help processors achieve higher efficiency, cleaner output, and lower maintenance costs. Connect with our experts to optimize your oil extraction line.

Service.

Western Canada

SEW-EURODRIVE CO.Vancouver Servicing: British Columbia | Alberta Saskatchewan | Manitoba Yukon | NWT | Nunavut 24/7/365 Service: 1.800.972.5481

Central Canada

SEW-EURODRIVE CO. Bramalea Servicing: Ontario 24/7/365 Service: 1.800.567.8039

Eastern Canada

SEW-EURODRIVE CO. Montreal

Servicing: Quebec | New Brunswick | Newfoundland & Labrador | Nova Scotia

Prince Edward Island.

24/7/365 Service: 1.800.361.2928