MEET KONRAD 4.0

- Konrad Kurylo

- P.Eng (ingénieur) Technical Sales SEW-Eurodrive Canada.

- E-mail Konrad

- Direct Line: 416.575.7721

- Industry Core Competencies

- Bio

- Articles

Industry Core Competencies

- Motion Control

- Automotive

- Food & Beverage

- Logistics

- Mining

- Industrial

Konrad's Profile:

Described by many as the true professional, who is approachable—you can expect to gain tremendous value from Konrad’s interpersonal qualities, technical knowledge, and his ability to take complex technical specifications, and translate them into terms his clients easily understand. Konrad’s value proposition is to sell on the principal of trust, and building relationships with his clients. “I’m not a drive component order taker, I sell solutions that deliver results and piece-of mind.”

Contact Konrad:

Articles

The Robot industry PODCAST

With Jim Beretta and Konrad Kurylo

Jim Beretta is the Brand and Marketing Consultant of Customer Attraction and The Host of the Robot Industry Podcast. Konrad and Jim discuss innovative and scalable Transport Assistance Systems, practical AGV solutions, and the variety of specific verticals that can benefit from the integration of Smart Tech into their system solutions.

Konrad Presents

What do you know about 4.0?

Aaron from ABI notices an uptick of Industry 4.0 technology being used in the European and Asian markets—In Canada? Not so much. Are Canadian companies the laggards of Industry 4.0? Are we missing out?

Konrad Presents

Robots Making our Coffee?

As if making coffee wasn’t easy enough. We’ve seen how robots can use sensors and actuation to move and build products in an industrial setting, but we’ve never seen a desktop robot barista. Coolness aside, do you think the retail coffee giants would even consider implementing these?

Konrad chats with Aaron from ABI about its robot barista demonstration. The robot is signaled to make coffee once it detects the cup. 4.0 Or 4.No?

Chime in on our social media channels.

Konrad Published in

Metal Working Magazine

Konrad Kurylo, P.Eng, article; “Get your shop AGV-ready” is published in the November issue of Canadian Metalworking Magazine! As a Seasoned System Solution Technical Sales Representative for MAXOLUTION®, Konrad shares his viewpoint on the safety and practical benefits of implementing an AGV solution.

VIEW

The number of required vehicles is subject to various conditions such as buffering stations, driving distances, single-track zones, passing lanes, location of vehicle depots, location of charging tracks, and charging times.

Safety is one of the biggest reasons that people turn to automated guided vehicles (AGVs). People suffer from fatigue and distraction, whereas an AGV is designed to do tedious routines 24/7. The last thing any shop wants is to lose an employee for health and safety reasons but also to a lack of job satisfaction. AGVs can take over those repetitive tasks, freeing up operators to do value-added, meaningful work.

Many people are confused by the acronym AGV, often assuming the A stands for autonomous. However, automated guided vehicles are quite different from autonomous guided vehicles. Obstacle avoidance, which is indicative of autonomous guided vehicles, is a key differentiator between the two. To dispel the confusion, labels like autonomous mobile robots (AMR) tend to be used for autonomous systems rather than automated ones.

One common misconception is assuming obstacle avoidance is necessary on the shop floor, which results in overpaying for features that might not make sense in all cases. AMRs have their place in warehouse logistics and commercial applications environments, which are constantly changing. However, shops must have an objective viewpoint to understand where this functionality is beneficial and where it could be detrimental to the process; where the implementation is impossible because of limited or complex driving environments; and where it has no value, like a fenced area.

AGVs are best-suited for assembly and production logistics, as the environment does not change. They are part of the sequential process (assembly on the vehicle itself) or feed the process (deliver parts). The paths, sources, and targets are all predefined, and no obstacle avoidance is needed.

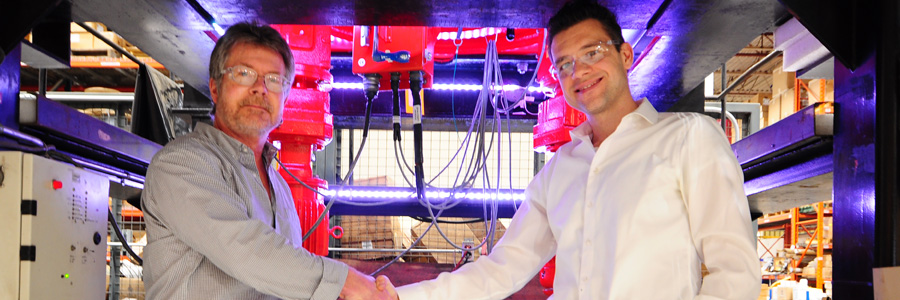

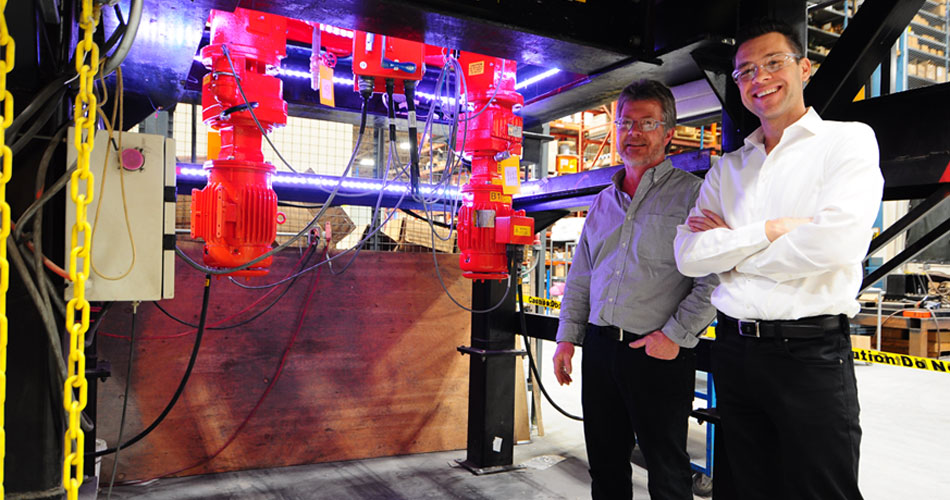

CPI Communications & Power Industries

TRUST IS ALWAYS ON THE RADAR

The military, aerospace and the telecom industries rely on companies like CPI to design and build vital communications systems. Having margins for errors that are slim to none, onboarding new partners that have a reputation for delivering on its promises are always on their radar. Ron from CPI explains.

Publishing a print advertisement and expecting someone to act on it doesn’t convert prospects to sales leads like it once did. Today, we are surrounded by digital content that tracks our likes, dislikes, and interests—all in an effort to sell us a product or influence our opinions.

Having the ability to digitally bookmark our favourite products, and find and connect with new people instantly, creates serious competition for sales people who prefer the traditional face-to-face approach. With the availability of these virtual interactions, do real-life one-to-one first impressions even stand a chance?

“Absolutely,” says thirty-five-year veteran Ron Venner, senior engineer in the Antenna Systems Division of CPI Communications & Power Industries (formerly ASC Signal). “With so many options for sourcing products and services available at our fingertips, I still believe there is something more potent than any search result, ad, or cold call—it’s a relationship built on trust. I am an engineer who manages a team of engineers, and trust is built into our products and our people, and it is what we look for in our partners—this is something no online search can find.”

CPI designs and builds antennas and communications systems for the military, aerospace, and telecom industries. Its products are vital communication gateways designed with redundant fail-safes that are made to withstand the elements and hostile environments.

In October 2016, CPI was awarded a contract to build multiple air traffic control radars—antennas that continually rotate, sending and receiving signals. Venner was tasked with sourcing a vendor that could supply and support the gear reducers needed to power the pedestal rotors. According to Venner, “The plan was to test and compare the durability, reliability, and seamless integration of two different brands of gear reducers. My first thought, even before the product, was sourcing a company and a representative I could trust—and Konrad was top of mind. I had dealt with Konrad many years ago while he was working with a different drive systems company. At that time, we had been experiencing performance issues with the gear reducers, which eventually led to a face-to-face meeting with Konrad and his employer.

What left me with a favourable impression of Konrad was how he conducted himself in this meeting. He came to the table with solutions, not additional problems. He upheld a neutral position—not taking sides; instead, he addressed the issues head-on, like a true professional. His demeanor painted a picture of someone who is genuine, fair, and trustworthy.

Based on my experiences with Konrad, my team and I felt that he would be the ideal choice to present a drive solution for this new project. I was genuinely eager to reconnect and explore the possibility of working with Konrad and SEW-Eurodrive.”

Upon completion of the endurance, performance, and quality testing phases, CPI concluded that SEW-Eurodrive possessed the solutions and level of support to meet its needs, and CPI continues to work with Konrad and SEW-Eurodrive on future endeavours.

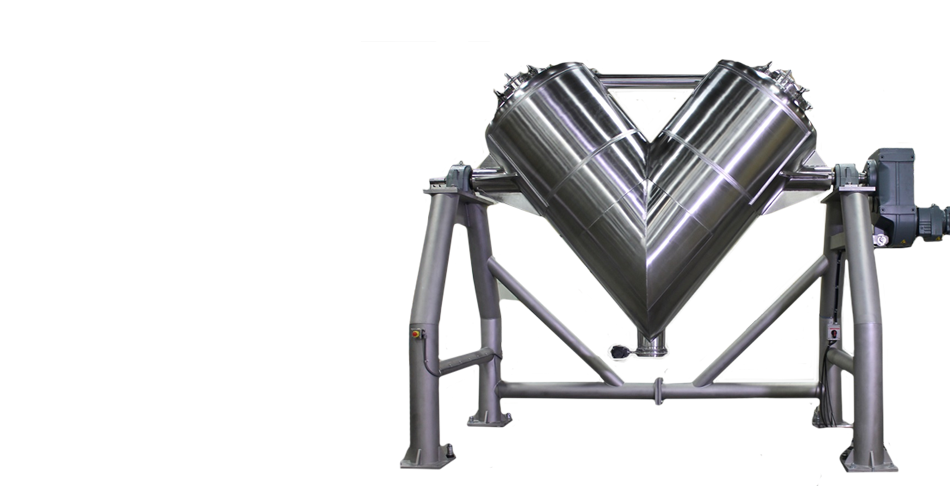

Ability Fabricators

Two parts siblings

Add two parts siblings with one part Eurodrive.

Ever heard the term, “You get what you pay for”? Does it hold any real significance in today’s business landscape when offshore “me-too” companies are claiming to produce equal quality products for lower costs? The SEW United crew traveled to Ability Fabricators in Concord, Ontario, to meet with the company’s founding partners (brothers) Ram and Basil Persaud, to discuss just that.

Ability Fabricators engineers and builds a variety of equipment for the pharmaceutical, food, and nutraceutical industries.

Its products range from conveyor systems and carts-to industrial mixers-and custom oversized V-blenders. The SEW United crew was interested in finding out what the Persauds considered to be the winning mix in today’s globalized marketplace.

Basil explains, “It’s blending added value with quality products”. We are competing against offshore companies that produce similar products for less, and their prices are used as leverage against us. We need to remind our prospective customers that their upfront costs are less, but they may end up paying a bigger price over the long term.

Imagine buying a new sofa, having it shipped to your home and then discovering it will not fit through your doorway. Did the salesperson really consider all the variables? Did he or she focus solely on making the sale? This analogy became a reality with a project lost to an offshore competitor. A V-blender arrived intact; however, the offshore OEM failed to consider the size of the doorway in which it needed to pass. What was the cost to break open the wall-or rip apart the roof to get the equipment in place? How do you quantify the aggravation, stress, and lost productivity?

Ram adds, “We do not glorify our company by pointing out the weak points of our competitors. There are many good ones out there—but the truth is they are offshore, and we are here. If things don’t go as planned, we are able to address and correct the problems quickly and effectively. The equipment we build is vital to our customers, and just like with anything you buy, it’s not only what you buy, it’s where you buy it.”

Basil chimes in: “Supporting Canadian businesses is very important to us. Not only does it support our economy, but it allows us the opportunity to meet our clients face to face. There will never be a substitute for interacting with clients in person; it allows us to see how they operate firsthand, what types of challenges they may face, and, most importantly, inspires us to innovate and improve what we do. These business rules are, in my opinion, a winning mix.

This mix does not only apply to how we sell; it funnels into how we buy. One of the many reasons we chose SEW-Eurodrive for our drive systems is because they share our belief that quality, care, and relationships mean more than just a good price. I also take great comfort in knowing that SEW-Eurodrive can support our drive systems regardless of where they are across Canada or the world.

“I appreciate SEW-Eurodrive’s system of recruiting specialized salespeople such as our designated representative Konrad Kurylo. In addition to being approachable and responsive, he brings a wealth of knowledge to the table because of his engineering background. This quality streamlines our process, and minimizes risk.

“I was asked if I felt that having the SEW-Eurodrive 24/7 support number was an added value to our purchase. I replied, I wouldn’t know because I never had to use it. Konrad’s cell phone is my hotline number; he picks up when I call and does a fantastic job. Again, this is what I call a winning mix.”

MacNeil Carwash

PARTNERSHIPS THAT SHINE

Have you ever been through a car wash and thought to yourself, What happens if this thing just stops? Well, fortunately, this is a rare occurrence when the car wash has been built by a company like MacNeil.

In Canada, many of our customers are corporately owned petroleum companies that build car wash systems as a complimentary service; however, our cross-border customers are very different.”

Ninety percent of MacNeil’s systems are exported to the United States, and because of Eurodrive’s proximity protocol, OEMs gain access to global support, regardless of where the products were purchased. Tulk explains: “Our US customers are very different from our Canadian customers. Our US customers are typically independent car wash owners/operators who live and breathe the car wash business every day. These business owners have extremely high expectations and demand a top-quality solution that performs, is easy to maintain, and generates profits. “Needless to say, they buy our products because our car wash systems are considered a premium brand that pairs high-volume capability with low maintenance and downtime. These demands are among the many reasons we use SEW-Eurodrive gear boxes as the driver for our car washes.

”I learned from my previous employer that SEW-Eurodrive has a reputation for quality; however, I didn’t elect to use their products solely based on performance; I looked at what level of support accompanies these products.

“SEW-Eurodrive has proven its value to us on many occasions; however, the shining moment for me was when we decided to switch our main conveyor motors from a competitor’s drive, to an SEW-Eurodrive. Aside from meeting our budgetary targets and significantly cutting down lead times, it was the post-sales support that impressed me the most. During the gear motor transition, our installers experienced technical challenges related to the wiring. Our sales representative Konrad Kurylo, who is also an engineer, was able to quickly identify the problem, isolate why it was happening, and go so far as to create a step-by-step video instructing us how to correct it. This video allowed us to resolve the problem locally and abroad.

“Having a great product without the support is a risky proposition in our business. Our philosophy is to work with companies that take accountability for what they do, stand behind their products, and have their people come to the table with solutions, not additional problems. This is truly a partnership that shines.”

Consetoga Cold Storage

everythings' cool

It started a little heated, but everything’s cool.

Frozen foods. What would we do without them? They are our saving grace for unexpected guests, and become a quick and easy dinner after a long day, with, of course, all the benefits of locked-in freshness and long shelf life.

Over the years, the SEW United Crew has witnessed many of Canada’s top food and beverage producers cook, bake and package their goods ready for distribution. If these goods were destined for the frozen food aisle, then the odds favour a quick detour through one of Conestoga Cold Storages’ warehouse and distribution facilities.

With five locations across Canada and a combined total of 42 Million cubic feet of storage, Conestoga Cold Storage has both the warehousing and distribution of cold and frozen foods down to a science.

The SEW United Crew visited Conestoga’s Mississauga facility and met with Vice President Gavin Sargeant, and Siegfried Giebat, electrical project manager, to learn more about what is involved in operating a successful high-volume cold storage operation.

In conversation with the SEW United Crew Giebat explains “Storage and distribution of cold and frozen foods is definitely on the rise—we store and ship all types of food products ranging from meats to baked goods for some of Canada’s largest food brands. With the increased demand, we are continually challenged to scale our operations without compromising the quality or service our customers expect. Our customers put a lot of trust in what we do; we are held accountable for storing and distributing goods that require special attention, and being just a few degrees off can have serious implications.”