Download the ABCs of AGVs.

Just give us some quick info about your business. Don’t worry we wont pester you with emails or phone calls.

AGVs- Automated Guided Vehicles MTS Series

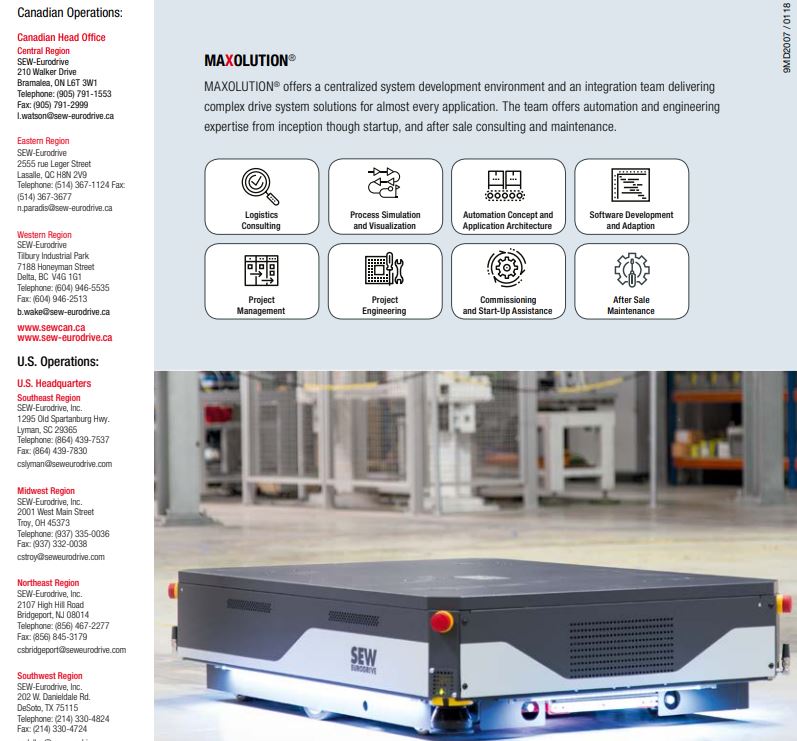

MAXOLUTION®

Automated Guided Vehicles MTS Series

MTS Series Automated Guided Vehicles overview.

(AGVs) are commonly used for material transfer, manufacturing assembly stations, flexible conveying systems, and many other plant production services. Mobile conveying vehicles are ideal for scalable factory automation.

What can AGV's be used for?

Automated Guided Vehicles (AGVs) are commonly used for material transfer, manufacturing assembly stations, flexible conveying systems, and many other plant production services.

Guidance Options

- SLAM Simultaneous Localization and Mapping

- Uses localization of natural structures with no tape

- Inductive line guidance sensor

- Very stable in rough environment, detects lane drift

- Optical line guidance sensor

- Detects lane drift to a colored tape, flexible for layout changes but not usable in rough environment

Contactless Energy Transfer

AGV’s can be powered or charged by our MOVITRANS® contactless energy transfer system. MOVITRANS® operates on the principle of inductive energy transfer, where electrical energy is transferred from a fixed conductor to one or more mobile consumers without contact. The electromagnetic connection is made via an air gap that runs 24/7 and is maintenance-free since there is no contact between the conductor and powered vehicle.

MAXOLUTION® offers a centralized system development environment and an integration team delivering complex drive system solutions for almost every application. The team offers automation and engineering expertise from inception though startup, and after sale consulting and maintenance. SEW-EURODRIVE’s MAXOLUTION® factory automation solutions consist of MTS Series intelligent vehicles, contactless energy transfer technology, WLAN communication, navigation options, and a wide variety of payload handling options. Combined with our gearmotors and control electronics, our MTS Series AGVs and factory automation components ensure a reliable and cost-effective system of material flow and in-plant logistics.

MTS SERIES SPECIFICATIONS

• Vehicle length from 845-2110mm

• Payload range from 500-3000kg

• Energy options for up to 24/7 runtime

• Inductive,optical,andfree-navigation guidance options

• Lead crystal battery power

• Inductive charging option

Capacity

55 AH

100AH

170AH

Weight

260 Kg

320 Kg

380 Kg

Weight

260 Kg

320 Kg

380 Kg

Weight

DRIVE CONFIGURATOR

AGVs- Automated Guide Vehicles

MAXOLUTION®

Automated Guided Vehicles (AGVs)

Automated guided vehicle systems (AGVs) ensure an automated in-house flow of materials, and are now used for assembly lines in many industrial sectors. The MAXOLUTION® AGVS system solutions consist of intelligent vehicles, contactless energy transfer systems and WLAN communication. They offer high flexibility and great practical benefits.

What’s included in the MAXOLUTION® AGV system solution?

The MAXOLUTION® Automated guided vehicle (AGV) system solution consists of intelligent vehicles, contactless energy transfer systems, and WLAN communication. Industrial AGV’s systems ensure an automated in-house flow of materials and are used for assembly lines in many industrial sectors.

AGV benefits

- Ability to minimize downtime

- Ability to improve efficiency

- 24 / 7 / 365 availability (AGV’s don’t sleep)

- Improved safety of your facility

- A scalable system that can reduce labour costs

- An established platform for full automation

- Modular and adaptable to accommodate for future expansions

What system is used to power AGVs?

AGVs are powered by our contactless energy transfer system—MOVITRANS®.

MOVITRANS® operates on the principle of inductive energy transfer. Electrical energy is transferred from a fixed conductor to one or more mobile consumers without contact. Time-consuming, cumbersome drag-chain systems have become a thing of the past.

The electromagnetic connection is made via an air gap and is maintenance-free and wear-free. This contactless energy supply enables high speeds of more than 10 m/s. And as line cables are routed under the floor, there are no longer any obstacles disrupting transverse traffic.

Advantages of using a contactless energy transfer system—MOVITRANS®.

Other advantages of integrating a contactless energy transfer system are its ability to run emission-free—resulting in a healthier work environment. MOVITRANS® is resistant to contamination and does not produce any noise emissions. These factors contribute to a better level of productivity, safety, and sustainable growth.